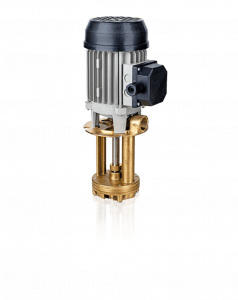

IMM immersion pumps with open impeller

Submersible pump in block design. Motor in dry installation and pump housing flooded by the medium to be pumped.

Impeller: open

Performance tables - IMM immersion pumps with open impeller

| Pump type | Delivery rate (min/max) | Delivery head (max/min) | Motor power (kW) |

|---|---|---|---|

| IMM 40 | 5 - 13 l/min | 2 - 0 m | 0.03 kW |

| IMM 50 | 3 - 22 l/min | 2,5 - 0 m | 0.04 kW |

| Pump type | Delivery rate (min/max) | Delivery head (max/min) | Motor power (kW) |

|---|---|---|---|

| IMM 63A | 8 - 85 l/min | 6 - 0 m | 0.25 kW |

| IMM 63B | 15 - 100 l/min | 8 - 0 m | 0.37 kW |

| Pump type | Delivery rate (min/max) | Delivery head (max/min) | Motor power (kW) |

|---|---|---|---|

| IMM 71A | 4 - 238 l/min | 14 - 0 m | 0.75 kW |

| IMM 71B | 6 - 240 l/min | 16 - 0 m | 0.9 kW |

| Pump type | Delivery rate (min/max) | Delivery head (max/min) | Motor power (kW) |

|---|---|---|---|

| IMM 80A | 14 - 293 l/min | 16 - 0 m | 1.1 kW |

| IMM 80B | 80 - 388 l/min | 18 - 0 m | 1.5 kW |

| Pump type | Delivery rate (min/max) | Delivery head (max/min) | Motor power (kW) |

|---|---|---|---|

| IMM 90A | 119 - 928 l/min | 10 - 0 m | 2.2 kW |

| IMM 90B | 172 - 1284 l/min | 14 - 0 m | 3 kW |

| IMM 100B | 50 - 1430 l/min | 18 - 0 m | 4 kW |

Downloads

Data sheet (incl. characteristic curves)