Interested in our premium pump solutions? Reach out to us today for a free consultation and a customized quote. Our dedicated team of experts is here to offer in-depth expertise and guide you to the ideal solution for your needs.

Alternatively, you can use our inquiry form.

Submersible pumps for clean and slightly dirty water manufactured in AISI 304 stainless steel. Head up to 20 metres, delivery up to 420 l/min (25,2 m3/h). Four basic models with 0,55 to 1,5 kW. DRIVELUB SEAL SYSTEM. Diffuser plate coated with polyurethane for the maximum resistance to abrasion.

Watertight electric motor protected by multiple seal system with oilchamber. A V-ring and silicon carbide mechanical seal (extremely resistant to wear and abrasion), as well as a lip seal which is continuosly lubricated by the DRIVELUB system, provide an extreme barrier against infiltration.

| Component | Material |

| Pump body Impeller |

Stainless steel EN 10088-1-X5CrNi18-10 (1.4301) AISI 304 |

| Suction flange | Stainless steel EN 10088-1-X5CrNi18-10 (1.4301) AISI 304 Polyurethan ( LARIPUR 9060 ) |

| Diffuser | ZITEL 70G30 |

| Mechanical seal | Silicon carbide / Silicon carbide / NBR (standard version) |

| Elastomers | NBR (standard version) |

| type | Rated Power | Q = Delivery | ||||||||||||

| l/min 0 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 300 | 325 | 375 | 420 | |||

| m³/h 0 | 6 | 7,5 | 9 | 10,5 | 12 | 13,5 | 15 | 18 | 19,5 | 22,5 | 25,2 | |||

| kW | HP | H = Total head metres column of water | ||||||||||||

| DIWA 05(T) | 0,55 | 0,75 | 10,9 | 8,6 | 7,9 | 7,1 | 6,3 | 5,5 | 4,7 | 3,8 | ||||

| DIWA 07(T) | 0,75 | 1 | 14 | 11,2 | 10,5 | 9,8 | 9 | 8,3 | 7,4 | 6,6 | 4,8 | 3,9 | ||

| DIWA 11(T) | 1,1 | 1,5 | 16,1 | 13,4 | 12,7 | 11,9 | 11,1 | 10,2 | 9,4 | 8,5 | 6,7 | 5,8 | 4 | |

| DIWA 15T | 1,5 | 2 | 20,6 | 17,3 | 16,4 | 15,6 | 14,8 | 14 | 13,1 | 12,2 | 10,4 | 9,4 | 7,3 | 5,3 |

| These performances are valid for liquids with density r = 1,0 kg/dm³ and kinematic viscosity n = 1 mm²/s. |

| type | Absorbed Power* |

Absorbed Current* |

capacitor | type | Absorbed Power* |

Absorbed Current* |

Absorbed Current* |

|

| 1 phase | 220-240 V | 3 phase | 220-240 V | 380-415 V | ||||

| kW | A | μF / 450 V | kW | A | A | |||

| DIWA 05 | 0,79 | 3,92 | 16 | DIWA 05T | 0,72 | 2,56 | 1,48 | |

| DIWA 07 | 1,25 | 6,2 | 22 | DIWA 07T | 1,2 | 4,26 | 2,46 | |

| DIWA 11 | 1,53 | 6,83 | 30 | DIWA 11T | 1,44 | 4,64 | 2,68 | |

| - | - | - | - | DIWA 15T | 2,05 | 6,74 | 3,89 |

| *Maximum values within operating range |

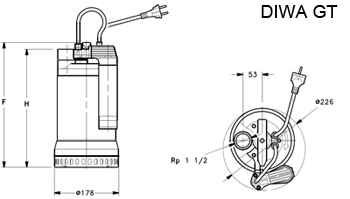

| Pump Type 1-phase |

dimensions (mm) | weight | ||

| F | H | kg | ||

| DIWA05 | DIWA05 GT | 348 | 330 | 12 |

| DIWA07 | DIWA07 GT | 393 | 375 | 14,3 |

| DIWA11 | DIWA11 GT | 393 | 375 | 17 |

| - | - | - | - | - |

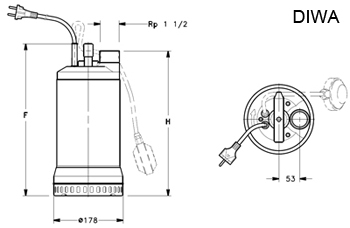

| Pump Type 3-phase |

dimensions (mm) | weight | |

| F | H | kg | |

| DIWA05T | 348 | 330 | 11 |

| DIWA07T | 363 | 345 | 13 |

| DIWA11T | 393 | 375 | 15 |

| DIWA15T | 393 | 375 | 16,5 |