Interested in our premium pump solutions? Reach out to us today for a free consultation and a customized quote. Our dedicated team of experts is here to offer in-depth expertise and guide you to the ideal solution for your needs.

Alternatively, you can use our inquiry form.

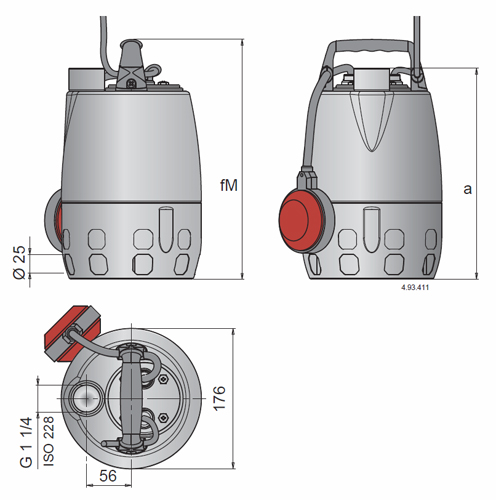

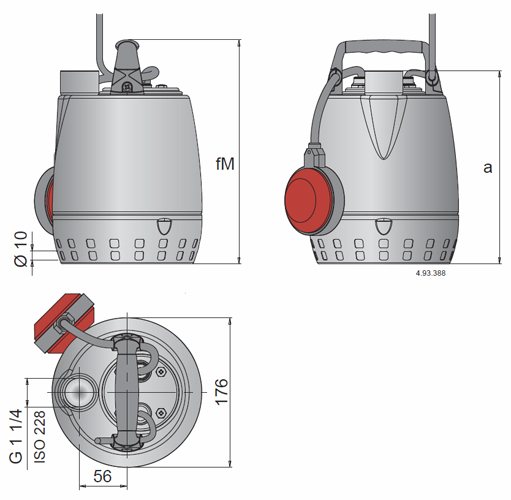

Single-impeller submersible pumps in chrome-nickel stainless steel, with vertical delivery port.

GXR: with open impeller.

GXV: with free-flow (vortex) impeller.

Motor cooled by the pumped water passing between the motor jacket and the external jacket. Double shaft seal with oil chamber. Minimum dimension and high levels of performance, for use in many different applications, head up to 12,7 m and flow rates up to 220 liters/min.

| Component | Material |

| Pump casing Strainer Impeller Motor jacket Pump jacket |

Chrome-nickel steel 1.4301 EN 10088 (AISI 304) |

| Handle | Polypropylene |

| Shaft | Chrome-nickel steel 1.4305 EN 10088 (AISI 303) |

| Mechanical seal | Ceramic alumina/Carbon/NBR |

| Seal lubrication oil | Oil for food/pharmaceutical machinery |

| 3-phase | 230V 400V | 1-phase | 230V | Capacitor | P1 | P2 | Q - m³/h | 0 | 1,2 | 3 | 4,5 | 6 | 7,5 | 9 | 10,2 | 12 | 13,2 | |||

| A | A | A | µf | Vc | kW | kW | HP | Q - l/min | 0 | 20 | 50 | 75 | 100 | 125 | 150 | 170 | 200 | 220 | ||

| GXR 9 | 1,6 | 0,9 | GXRM 9 | 2,5 | 8 | 450 | 0,5 | 0,25 | 0,33 | H (m) |

9 | 8,3 | 7 | 6 | 4,8 | 3,6 | 2,5 | 1,7 | ||

| GXR 11 | 2,3 | 1,3 | GXRM 11 | 3,5 | 12,5 | 450 | 0,7 | 0,37 | 0,5 | 11 | 10,4 | 9,5 | 8,5 | 7,5 | 6,5 | 5,3 | 4,2 | 2,2 | ||

| GXR 13 | 2,8 | 1,6 | GXRM 13 | 4,5 | 16 | 450 | 0,95 | 0,45 | 0,6 | 12,7 | 11,7 | 10,7 | 9,7 | 8,5 | 7,3 | 6,3 | 5,2 | 3,2 | 2 | |

| P1 Max. power input. | P2 Rated motor power output. | Density: 1000 kg/m3. |

| Kinematic viscosity: max 20 mm2/sec. | Tolerances according to ISO 9906, annex A. | |

| 3-phase | 230V 400V | 1-phase | 230V | Capacitor | P1 | P2 | Q - m³/h | 0 | 1,2 | 3 | 4,5 | 6 | 7,5 | 9 | 10,2 | 12 | 13,2 | |||

| A | A | A | µf | Vc | kW | kW | HP | Q - l/min | 0 | 20 | 50 | 75 | 100 | 125 | 150 | 170 | 200 | 220 | ||

| GXV 25-6 | 1,6 | 0,9 | GXVM 25-6 | 2,5 | 8 | 450 | 0,5 | 0,25 | 0,33 | H (m) |

6 | 5,7 | 5,2 | 4,5 | 3,8 | 3 | 2,2 | 1,5 | ||

| GXV 25-8 | 2,3 | 1,3 | GXVM 25-8 | 3,5 | 12,5 | 450 | 0,7 | 0,37 | 0,5 | 8,2 | 7,8 | 7,2 | 6,7 | 6,1 | 5,4 | 4,5 | 3,6 | 2,2 | ||

| GXV 25-10 | 2,8 | 1,6 | GXVM 25-10 | 4,5 | 16 | 450 | 0,95 | 0,45 | 0,6 | 10 | 9,5 | 8,7 | 8 | 7,3 | 6,5 | 5,7 | 4,9 | 3,7 | 2,6 | |

| P1 Max. power input. | P2 Rated motor power output. | Density: 1000 kg/m3. |

| Kinematic viscosity: max 20 mm2/sec. | Tolerances according to ISO 9906, annex A. | |

| TYPE | Dimensions (mm) | kg | ||

| H | H1 | GXR | GXRM | |

| GXR 9 -GXRM 9 | 265 | 230 | 5 | 5,2 |

| GXR 11 -GXRM 11 | 300 | 265 | 6,2 | 6,5 |

| GXR 13 -GXRM 13 | 300 | 265 | 6,7 | 7,2 |

| TYPE | Dimensions (mm) | kg | ||

| H | H1 | GXV | GXVM | |

| GXV 25-6 -GXVM 25-6 | 302 | 267 | 5,1 | 5,3 |

| GXV 25-8 -GXVM 25-8 | 337 | 302 | 6,3 | 6,6 |

| GXV 25-10 -GXVM 25-10 | 337 | 302 | 6,8 | 7,3 |