Interested in our premium pump solutions? Reach out to us today for a free consultation and a customized quote. Our dedicated team of experts is here to offer in-depth expertise and guide you to the ideal solution for your needs.

Alternatively, you can use our inquiry form.

chrome-nickel stainless steel

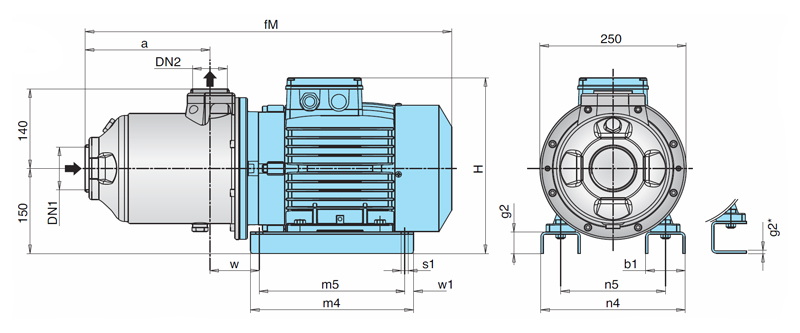

Horizontal multi-stage close coupled pumps in chrome-nickel stainless steel. Compact and robust construction,with compact lantern bracket and motor with feet. Single-piece barrel casing, with front suction port above pumps axis and radial delivery at top. Filling and draining plugs on the middle of the pump, accessible from any side (like the terminal box).

For water supply. For clean liquids, without abrasives, which are non-aggressive for stainless steel (with suitable seal materials, on request).

Universal pump, for civil and industrial applications, for garden use and irrigation.

Liquid temperature from - 15 °C to + 110 °C.

Ambient temperature up to 40 °C.

Maximum permissible pressure in the pump casing: 10 bar.

2-pole induction motor, 50 Hz (n = 2900 rpm).

MXH: three-phase 230/400 V ± 10% up to 3 kW;

400/690 V ± 10% from 4 to 7,5 kW. Insulation class F. Protection IP 54.

Classification scheme IE2.

Constructed in accordance with: EN 60034-1; EN 60034-30.

| Component | MXH, MXHM |

| Pump casing Stage casing Wear ring Casing cover Spacer sleeve |

Chrome-nickel steel 1.4301 EN 10088 (AISI 304) |

| Spaltring | PTFE |

| Pump shaft Plug |

Chrome-nickel steel 1.4305 EN 10088 (AISI 303) |

| Mechanical seal with seat according to ISO 3069-KU |

Ceramic alumina, carbon, EPDM (Other materials on request) |

| 3-phasig | 230V | 400V | P2 | Q m³/h |

0 | 15 | 21 | 24 | 27 | 30 | 33 | 36 | 39 | 44 | 50 | |

| A | A | kW | HP | I/min | 0 | 250 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 733 | 833 | |

| MXH3201/A | 9,15 | 5,3 | 2,2 | 3 | H (m) |

18,4 | 16,3 | 15,3 | 14,8 | 14 | 13 | 12 | 10,8 | 9,3 | 6 | - |

| MXH3202/A | 9,6 | 4 | 5,5 | 37 | 33 | 31 | 30 | 28,5 | 27 | 25 | 23 | 20,5 | 15 | 7,5 | ||

| MXH3203/A | 12 | 5,5 | 7,5 | 55,5 | 50 | 47 | 45,5 | 43 | 40,5 | 38 | 35 | 31 | 23 | 10 | ||

| MXH3204/A | 16 | 7,5 | 10 | 74,5 | 67 | 63 | 61 | 59 | 56 | 53 | 49 | 44 | 34 | 16,5 | ||

| H Gesamtförderhöhe in m. | Versuchsergebnisse mit sauberem und kaltem Wasser, ohne Gasgehalt. | |

| P2 MotorRated Power. | Toleranzen nach ISO 9906, Anhang A. | Ein Sicherheitszuschlag von + 0,5 m auf dem NPSH-Wert ist erforderlich. |

| 3-phasig | 230V | 400V | P2 | Q m³/h |

0 | 21 | 27 | 33 | 39 | 45 | 48 | 51 | 54 | 60 | 66 | |

| A | A | kW | HP | I/min | 0 | 350 | 450 | 550 | 650 | 750 | 800 | 850 | 900 | 1000 | 1100 | |

| MXH 4801/A | 11 ,5 | 6,6 | 3 | 4 | H (m) |

20 | 18 | 17 | 16 | 14,5 | 12,5 | 11 ,5 | 10,5 | 9,5 | 7 | - |

| MXH4802/A | 12 | 5,5 | 7,5 | 41 | 35,3 | 33 | 30,5 | 27,5 | 24,5 | 22,5 | 21 | 19 | 14 | 7,5 | ||

| MXH4803/A | 16 | 7,5 | 10 | 60,5 | 53 | 50 | 46 | 42,5 | 38 | 35 | 32,5 | 29 | 22,5 | 16 | ||

| H Gesamtförderhöhe in m. | Versuchsergebnisse mit sauberem und kaltem Wasser, ohne Gasgehalt. | |

| P2 MotorRated Power. | Toleranzen nach ISO 9906, Anhang A. | Ein Sicherheitszuschlag von + 0,5 m auf dem NPSH-Wert ist erforderlich. |

Threaded ports

| TYPE | DN1 | DN2 | mm | kg | |||||||||||||

| ISO228 | L | L1 | L2 | h3 | m1 | m2 | n1 | n2 | z | b | s | w | g1 | g2 | |||

| MXH 3201/A | G 2 ½ | G2 | 501 | 120,5 | 216 | 280 | 205 | 175 | 170 | 130 | 15 | 54 | 10 | 92,5 | 6 | 29,4 | |

| MXH 3202/A | G 2 ½ | G2 | 515 | 120,5 | 233 | 290 | 205 | 175 | 180 | 140 | 15 | 54 | 10 | 112 | 6 | 38,5 | |

| MXH 3203/A | G 2 ½ | G2 | 582 | 166,5 | 251 | 310 | 280 | 250 | 258 | 190 | 15 | 68 | 12 | 84 | 38 | 50 | |

| MXH 3204/A | G 2 ½ | G2 | 628 | 212,5 | 297 | 310 | 280 | 250 | 258 | 190 | 15 | 68 | 12 | 84 | 38 | 57,5 | |

| MXH 4801/A | G3 | G 2 ½ | 545 | 136 | 263 | 290 | 205 | 175 | 180 | 140 | 15 | 54 | 10 | 128,5 | 6 | 38 | |

| MXH 4802/A | G3 | G 2 ½ | 566 | 136 | 235 | 310 | 280 | 250 | 258 | 190 | 15 | 68 | 12 | 100 | 38 | 49,5 | |

| MXH 4803/A | G3 | G 2 ½ | 628 | 197,5 | 297 | 310 | 280 | 250 | 258 | 190 | 15 | 68 | 12 | 100 | 38 | 58 | |

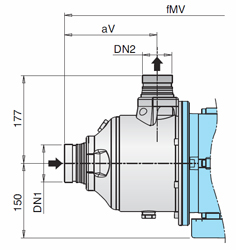

Victaulic ports

| TYPE | DN1 | DN2 | mm | ||

| mm | mm | LV | L1V | L2V | |

| MXH-V 3201/A | 76,1 (DN65) | 60,3 (DN50) | 541 | 160 | 256 |

| MXH-V 3202/A | 76,1 (DN65) | 60,3 (DN50) | 555 | 160 | 273 |

| MXH-V 3203/A | 76,1 (DN65) | 60,3 (DN50) | 622 | 206 | 291 |

| MXH-V 3204/A | 76,1 (DN65) | 60,3 (DN50) | 668 | 252 | 337 |

| MXH-V 4801/A | 88,9 (DN80) | 76,1 (DN65) | 585 | 175 | 303 |

| MXH-V 4802/A | 88,9 (DN80) | 76,1 (DN65) | 606 | 175 | 275 |

| MXH-V 4803/A | 88,9 (DN80) | 76,1 (DN65) | 668 | 237 | 337 |

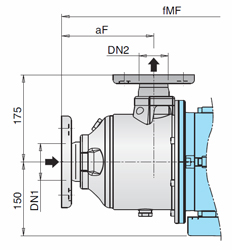

Flange-connections

| TYPE | DN1 | DN2 | mm | ||

| mm | mm | LF | L1F | L2F | |

| MXH-F 3201/A | 65 | 50 | 531 | 151 | 246 |

| MXH-F 3202/A | 65 | 50 | 545 | 151 | 263 |

| MXH-F 3203/A | 65 | 50 | 612 | 197 | 281 |

| MXH-F 3204/A | 65 | 50 | 658 | 243 | 327 |

| MXH-F 4801/A | 80 | 65 | 565 | 156 | 283 |

| MXH-F 4802/A | 80 | 65 | 586 | 156 | 255 |

| MXH-F 4803/A | 80 | 65 | 648 | 218 | 317 |

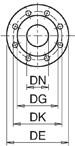

Flansch* EN 1092-2

| DN | DE | DK | DG | Löcher | |

| N. | Ø | ||||

| 50 | 165 | 125 | 99 | 4 | 19 |

| 65 | 185 | 145 | 118 | 4 | 19 |

| 80 | 200 | 160 | 132 | 8 | 19 |

* ASME 150 lb (ex ANSI 150 lb)