Interested in our premium pump solutions? Reach out to us today for a free consultation and a customized quote. Our dedicated team of experts is here to offer in-depth expertise and guide you to the ideal solution for your needs.

Alternatively, you can use our inquiry form.

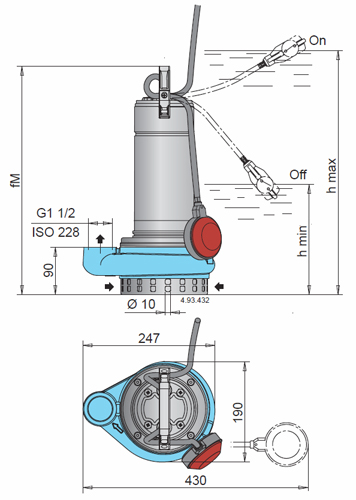

Single-impeller submersible drainage pump, with vertical delivery port.

GQR: with open impeller. Double mechanical shaft seal with interposed oil chamber, to protect against dry-running.

| Component | Material |

| Pump casing Impeller |

Cast iron GJL 200 EN 1561 |

| Strainer Motor jacket Jacket cover |

Chrome-nickel steel 1.4301 EN 10088 (AISI 304) |

| Handle | Polypropylene (with frame in AISI 304) |

| Shaft | Chrome-nickel steel 1.4305 EN 10088 (AISI 303) |

| Mechanical seal: upper Mechanical seal: lower |

Ceramic alumina/Carbon/NBR |

| Seal lubrication oil | Oil for food/pharmaceutical machinery |

| 3-phase | 230V | 400V | 1-phase | 230V | Capacitor | P1 | p2 | Q - m³/h | 0 | 3 | 6 | 9 | 12 | 15 | 18 | 21 | 24 | 27 | 30 | ||

| A | A | A | µf | Vc | kW | kW | HP | Q - l/min | 0 | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | ||

| GQR 10-10 | 2 | 1,2 | GQRM 10-10 | 3,1 | 12,5 | 450 | 0,7 | 0,45 | 0,6 | H (m) |

10 | 9,5 | 8,8 | 8 | 6,7 | 5 | 3 | - | - | - | - |

| GQR 10-12 | 2,4 | 1,4 | GQRM 10-12 | 3,6 | 16 | 450 | 1 | 0,55 | 0,75 | 12 | 11,6 | 11 | 10,2 | 9 | 7,5 | 5,5 | 3,2 | - | - | - | |

| GQR 10-14 | 2,8 | 1,6 | GQRM 10-14 | 4,6 | 16 | 450 | 1 | 0,75 | 1 | 14 | 13,5 | 12,8 | 12 | 10,8 | 9,3 | 7,5 | 5,5 | 3 | - | - | |

| GQR 10-16 | 4 | 2,3 | GQRM 10-16 | 6 | 25 | 450 | 1,3 | 0,9 | 1,2 | 16 | 15,5 | 15 | 14,2 | 13,2 | 11,8 | 10,2 | 8 | 5,5 | 2,3 | - | |

| GQR 10-18 | 4,8 | 2,8 | GQRM 10-18 | 8 | 30 | 450 | 1,7 | 1,1 | 1,5 | 18 | 17,5 | 17 | 16,2 | 15 | 13,7 | 11,8 | 9 | 7 | 4,3 | 1,5 | |

| GQR 10-20 | 6,6 | 3,8 | 1,5 | 2 | 20 | 19,5 | 18,8 | 18 | 16,8 | 15,2 | 13,2 | 10,8 | 8,4 | 5,7 | 3 | ||||||

| P1 Max. power input. | P1 Max. power input. | |

| Density ρ = 1000 kg/m3. | Kinematic viscosity ν = max 20 mm2/sec. | |

| TYPE | mm | kg | |||

| H | h max | h min | GQR | GQRM | |

| GQR(M) 10-10 | 390 | 410 | 205 | 14 | 15 |

| GQR(M) 10-12 | 405 | 425 | 220 | 14,5 | 15,5 |

| GQR(M) 10-14 | 405 | 425 | 220 | 14,5 | 15,5 |

| GQR(M) 10-16 | 430 | 450 | 245 | 16 | 18 |

| GQR(M) 10-18 | 450 | 470 | 265 | 17,5 | 19 |

| GQR 10-20 | 450 | 470 | 265 | 19 | - |