Interested in our premium pump solutions? Reach out to us today for a free consultation and a customized quote. Our dedicated team of experts is here to offer in-depth expertise and guide you to the ideal solution for your needs.

Alternatively, you can use our inquiry form.

Applications

For clean liquids without abrasives, without suspended solids, non-explosive, non-aggressive for the pump materials. For increasing network pressure (follow local specifications). For the reduced dimensions, these pumps are very well suitable to be mounted in cooling and air-conditioning machines and equipments, circulation, boiler feed.

Operating conditions

Liquid temperature from -10 °C to +90 °C.

Ambient temperature up to 40 °C.

Total suction lift up to 7 m. Continuous duty.

Motor

2-pole induction motor, 50 Hz (n = 2900 rpm).

T, TP: three-phase 230/400 V ± 10% up to 3 kW; 400/690 V ± 10% from 4 to 7,5 kW;

TM, TPM: single-phase 230 V ± 10% with thermal protector. Capacitor inside the terminal box. Insulation class F.

Protection IP 54. Classification scheme IE2 for three-phase motors from 0,75 kW.

Constructed in accordance with: EN 60034-1; EN 60034-30. EN 60335-1, EN 60335-2-41.

Special features on request

- Other voltages.

- Frequency 60 Hz (as per 60 Hz data sheet).

- Protection IP 55.

- Special mechanical seal.

- Higher or lower liquid or ambient temperatures.

| Components | T, TP | B-T, B-TP |

| Pump casing |

Cast iron GJL 200 EN 1561 | Bronze G-Cu Sn 10 EN 1982 |

| Lantern bracket | Cast iron GJL 200 EN 1561 | Bronze G-Cu Sn 10 EN 1982 |

| Casing cover | Cast iron GJL 200 EN 1561 | Bronze G-Cu Sn 10 EN 1982 |

| Brass P- Cu Zn 40 Pb 2 UNI 5705 für T 61-65-70, B-T 61-70 | ||

| Impeller | Brass P- Cu Zn 40 Pb 2 UNI 5705 Bronze G-Cu Sn 10 EN 1982 für T 125, TP 132-132R |

|

| Shaft | Cr-Ni steel 1.4305 (AISI 303) T 76, TP 80-100 |

Cr-Ni-Mo steel 1.4401 (AISI 316) |

| Chrome steel 1.4104 (AISI 430) T 61-65-70-100-125, TP 78-132-132R |

||

| Mechanical seal | Carbon - Ceramic - NBR | |

| 3~ | 230V | 400V | 1~ | 230V | P1 | P2 | Q m³/h |

0,06 | 0,12 | 0,24 | 0,38 | 0,48 | 0,6 | 0,75 | 1 | 1,2 | 1,5 | 1,89 | 2,4 | 3 | 3,6 | |

| A | A | A | kW | kW | HP | l/min | 1 | 2 | 4 | 6,3 | 8 | 10 | 12,5 | 16 | 20 | 25 | 31,5 | 40 | 50 | 60 | ||

| B-T 61E | 1,9 | 1,1 | B-TM 61E | 2,5 | 0,55 | 0,33 | 0,45 | H (m) |

38 | 36 | 34 | 31,5 | 28 | 24 | 19 | 12,5 | 5 | |||||

| T 65E | 2,8 | 1,6 | TM 65E | 3,5 | 0,8 | 0,45 | 0,6 | 44 | 42 | 40 | 37 | 33 | 29 | 24 | 16 | 8 | ||||||

| B-T 70/A | 3,7 | 2,2 | B-TM 70/A | 6 | 1,3 | 0,75 | 1 | 59 | 57 | 55 | 51 | 48 | 43 | 38 | 30 | 22 | 10 | |||||

| T76E | 5,3 | 3 | TM76E | 7,4 | 1,6 | 1,1 | 1,5 | 70 | 68 | 67 | 65 | 62 | 58 | 53 | 46 | 38 | 26 | |||||

| B-TP 78/A | 2,3 | 1,3 | B-TPM 78/A | 2,8 | 0,6 | 0,37 | 0,5 | 75 | 70 | 60 | 50 | 42 | 35 | 25 | 15 | |||||||

| B-TP 80E | 3,3 | 1,9 | B-TPM 80E | 5,8 | 1,2 | 0,75 | 1 | 85 | 79 | 73 | 61 | 48 | 34 | 20 | ||||||||

| TP 100/A | 9,6 | 5,5 | 2,2 | 3 | 160 | 157 | 151 | 140 | 129 | 115 | 99 | 82 | ||||||||||

| P1 Maximum power input. | B-T, B-TM = Bronze construction. | H Total head in m. |

| P2 Rated motor power output. | * Maximum suction lift 2-3 m. | |

| 3~ | 230V | 400V | P2 | Q m³/h |

1,89 | 2,4 | 3 | 3,6 | 4,2 | 4,8 | 5,4 | 6 | |

| A | A | kW | HP | l/min | 31,5 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | |

| T 100/A | 11,5 | 6,6 | 3 | 4 | H (m) |

103 | 97 | 89 | 82 | 75 | 68 | ||

| T 125/A | 9,6 | 4 | 5,5 | 125 | 110 | 90 | 75* | 60* | |||||

| TP 132R/A | 10,9 | 5,5 | 7,5 | 145 | 135 | 120 | 110 | 95 | 70 | ||||

| TP 132/A | 14,3 | 7,5 | 10 | 165 | 143* | 120* | |||||||

| P1 Maximum power input. | B-T, B-TM = Bronze construction. | H Total head in m. |

| P2 Rated motor power output. | * Maximum suction lift 2-3 m. | |

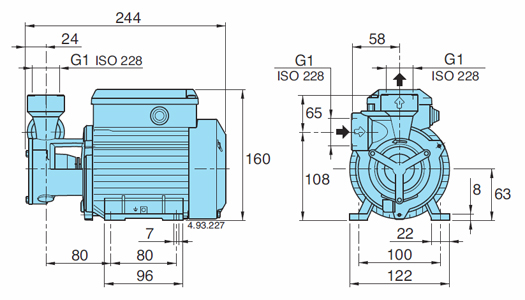

| Type | DN1 | DN2 | mm | kg | |||||

| ISO 228 | a | f | h2 | h3 | I2 | T | B-T | ||

| T 70/A B-T 70/A | G1 | G1 | 24 | 278 | 100 | 121 | 63 | 11,2 | 11,6 |

| TP 78/A B-TP781A | G ½ | G ½ | 22 | 276 | 80 | 127 | 56 | 8,2 | 8,8 |

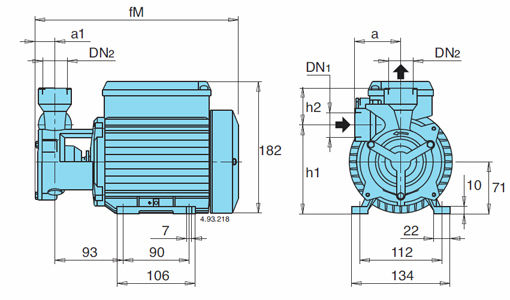

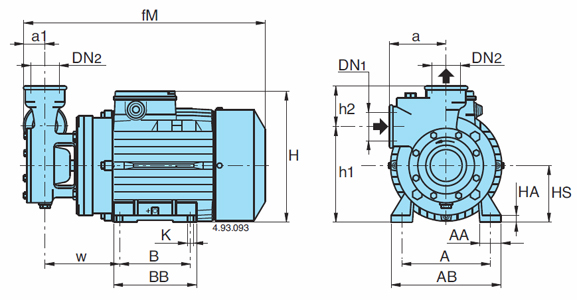

| Type | DN1 | DN2 | mm | kg | |||||||||||||||

| ISO 228 | a | f | h1 | h2 | h3 | h4 | m1 | m2 | n1 | n2 | b | s | I2 | w | g | T, TP | B-TP | ||

| T 76E | G 1¼ | G 1¼ | 26 | 338 | 80 | 112 | 136 | 203 | 117 | 100 | 155 | 125 | 30 | 9 | 80 | 105 | 10 | 18,4 | - |

| T 100/A | G 1¼ | G 1¼ | 32 | 410 | 90 | 130 | 161 | 226 | 152 | 125 | 180 | 140 | 40 | 9,5 | 95 | 121 | 12 | 32,5 | - |

| T125/A | G 1¼ | G 1¼ | 32 | 470 | 90 | 155 | 170 | 226 | 152 | 125 | 180 | 140 | 40 | 9,5 | 90 | 195 | 12 | 39,5 | - |

| (B-)TP 80E | G ¾ | G ¾ | 27 | 332 | 80 | 90 | 135 | 203 | 117 | 100 | 155 | 125 | 30 | 9 | 60 | 104 | 10 | 16,4 | 16,8 |

| TP 100/A | G ¾ | G ¾ | 27 | 387 | 80 | 100 | 142 | 203 | 117 | 100 | 155 | 125 | 30 | 9 | 65 | 113 | 10 | 23,2 | - |

| TP 132R/A | G 1¼ | G 1¼ | 42 | 485 | 112 | 160 | 202 | 272 | 180 | 140 | 230 | 190 | 50 | 11 ,5 | 100 | 183 | 14 | 53,6 | -- |

| TP 132/A | G 1¼ | G 1¼ | 42 | 485 | 112 | 160 | 202 | 272 | 180 | 140 | 230 | 190 | 50 | 11 ,5 | 100 | 183 | 14 | 58,5 | -- |