Interested in our premium pump solutions? Reach out to us today for a free consultation and a customized quote. Our dedicated team of experts is here to offer in-depth expertise and guide you to the ideal solution for your needs.

Alternatively, you can use our inquiry form.

CIVIL, INDUSTRIAL.

| Components | CO, COM |

| Pump body Impeller Seal housing Shaftnende |

Stainless steel EN 10088-1-X2CrNiMo17-12-2 1.4404 (AISI 316L) |

| Impellermutter und Scheibe Füll- und EntleerungsScrews |

Stainless steel EN 10088-1-X5CrNiMo17-12-2 1.4401 (AISI 316) |

| O-Ring | FPM (Standard) |

| Mechanical seal | Ceramic / Carbon / FPM (Standard) |

| Adapter | Aluminium EN 1706-AC-AlSi11Cu2(Fe)DF (ASTM Class 25) |

| GehäuseScrews | Galvanized steel |

| ELECTRIC PUMP TYPE |

RATED POWER | Q = DELIVERY | ||||||||||||||||||

| l/min 0 | 100 | 120 | 160 | 200 | 240 | 280 | 300 | 350 | 375 | 400 | 450 | 500 | 600 | 650 | 700 | 800 | 900 | |||

| m³/h 0 | 6 | 7,2 | 9,6 | 12 | 14,4 | 16,8 | 18 | 21 | 22,5 | 24 | 27 | 30 | 36 | 39 | 42 | 48 | 54 | |||

| kW | HP | H = TOTAL HEAD METRES COLUMN OF WATER | ||||||||||||||||||

| CO(M) 350/03 | 0,37 | 0,5 | 9,5 | 6,8 | 6,3 | 5,5 | 4,8 | 4,1 | 3,4 | 3 | ||||||||||

| CO(M) 350/05 | 0,55 | 0,75 | 12 | 9,2 | 8,8 | 7,9 | 7,1 | 6,3 | 5,5 | 5,1 | 4 | |||||||||

| CO(M) 350/07 | 0,75 | 1 | 13,7 | 11,2 | 10,8 | 9,9 | 9,1 | 8,2 | 7,4 | 6,9 | 5,8 | 5,3 | ||||||||

| CO(M) 350/09 | 0,9 | 1,2 | 15,7 | 12,7 | 12,2 | 11,3 | 10,5 | 9,6 | 8,8 | 8,3 | 7,2 | 6,6 | 5,9 | |||||||

| CO(M) 350/11 | 1,1 | 1,5 | 17,3 | 14,3 | 13,8 | 12,9 | 12 | 11,2 | 10,5 | 10,1 | 9,1 | 8,6 | 8 | 6,8 | ||||||

| CO(M) 350/15 | 1,5 | 2 | 20,3 | 16,9 | 16,4 | 15,3 | 14,4 | 13,5 | 12,7 | 12,2 | 11,2 | 10,6 | 10 | 8,7 | 7,2 | |||||

| CO(M) 500/15 | 1,5 | 2 | 16 | 13,4 | 12,8 | 12,3 | 12 | 11,3 | 10,9 | 10,5 | 9,8 | 9 | 7,4 | 6,6 | 5,8 | |||||

| CO(M) 500/22 | 2,2 | 3 | 19,6 | 17,3 | 16,7 | 16,2 | 15,9 | 15,2 | 14,9 | 14,5 | 13,7 | 13 | 11,3 | 10,4 | 9,6 | 7,7 | ||||

| CO 500/30 | 3 | 4 | 24,1 | 20,9 | 20,3 | 19,7 | 19,3 | 18,5 | 18,1 | 17,7 | 16,9 | 16 | 14,3 | 13,5 | 12,6 | 10,8 | 9 | |||

| PUMP TYPE 1~ |

INPUT POWER* kW |

INPUT CURRENT* 220-240 V A |

CAPACIT. ìF / 450 V |

PUMP TYPE 3~ |

INPUT POWER* kW |

INPUT CURRENT* 220-240 V A |

INPUT CURRENT* 380-415 V A |

|

| COM350/03 | 0,63 | 2,82 | 14 | C0 350/03 | 0,64 | 2,53 | 1,46 | |

| COM350/05 | 0,88 | 4,25 | 16 | CO 350/05 | 0,79 | 2,7 | 1,56 | |

| COM350/07 | 1,02 | 4,67 | 20 | C0 350/07 | 1 | 3,57 | 2,06 | |

| COM350/09 | 1,21 | 5,46 | 25 | CO 350/09 | 1,13 | 4,21 | 2,43 | |

| COM350/11 | 1,75 | 7,85 | 30 | C0 350/11 | 1,69 | 5,2 | 3 | |

| COM350/15 | 2,04 | 9,21 | 40 | CO 350/15 | 1,98 | 6,3 | 3,64 | |

| COM500/15 | 2,02 | 9,12 | 40 | C0 500/15 | 1,96 | 6,27 | 3,62 | |

| COM500/22 | 2,71 | 12,1 | 50 | CO 500/22 | 2,73 | 9,06 | 5,23 | |

| - | - | - | - | C0 500/30 | 3,97 | 11,7 | 6,78 |

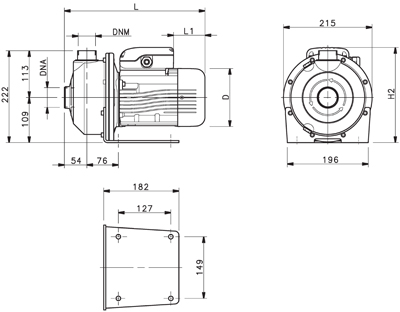

| PUMP TYPE | Dimensions ( mm ) | DNA | DNM | kg | |||

| D | H2 | L | L1 | ||||

| COM 350/03 | 120 | 220 | 325 | 62 | Rp 1 ½ | Rp 1 ¼ | 10 |

| COM 350/05 | 140 | 230 | 339 | 76 | Rp 1 ½ | Rp 1 ¼ | 11,9 |

| COM 350/07 | 140 | 230 | 339 | 76 | Rp 1 ½ | Rp 1 ¼ | 12,6 |

| COM 350/09 | 140 | 239 | 339 | 31 | Rp 1 ½ | Rp 1 ¼ | 13,2 |

| COM 350/11 | 156 | 246 | 385 | 69 | Rp 1 ½ | Rp 1 ¼ | 14,5 |

| COM 350/15 | 156 | 246 | 385 | 69 | Rp 1 ½ | Rp 1 ¼ | 16,2 |

| COM 500/15 | 156 | 246 | 385 | 69 | Rp 2 | Rp 1 ½ | 16,2 |

| COM 500/22 | 176 | 230 | 416 | 114 | Rp 2 | Rp 1 ½ | 17,8 |

| CO 350/03 | 120 | 220 | 325 | 62 | Rp 1 ½ | Rp 1 ¼ | 10 |

| CO 350/05 | 140 | 230 | 339 | 76 | Rp 1 ½ | Rp 1 ¼ | 11,9 |

| CO 350/07 | 140 | 230 | 339 | 76 | Rp 1 ½ | Rp 1 ¼ | 12,6 |

| CO 350/09 | 140 | 230 | 339 | 76 | Rp 1 ½ | Rp 1 ¼ | 12,2 |

| CO 350/11 | 156 | 238 | 385 | 114 | Rp 1 ½ | Rp 1 ¼ | 14,5 |

| CO 350/15 | 156 | 238 | 385 | 114 | Rp 1 ½ | Rp 1 ¼ | 16,2 |

| CO 500/15 | 156 | 238 | 385 | 114 | Rp 2 | Rp 1 ½ | 16,2 |

| CO 500/22 | 156 | 238 | 385 | 114 | Rp 2 | Rp 1 ½ | 17,8 |

| CO 500/30 | 176 | 230 | 416 | 149 | Rp 2 | Rp 1 ½ | 22 |