Interested in our premium pump solutions? Reach out to us today for a free consultation and a customized quote. Our dedicated team of experts is here to offer in-depth expertise and guide you to the ideal solution for your needs.

Alternatively, you can use our inquiry form.

Submersible Pumps for 4" - deep wells

Market sectors

civil, agricultural, industrial.

Application

Water supply, sprinkler irrigation, pressure boosting, fire-fighting.

Abrasion-resistant construction. The front wear plate, combined with the floating impellers, ensures optimum resistance to abrasion.

The upper and lower supports are made of precision-cast stainless steel, ensuring resistance to corrosion, durability and a sturdy coupling to the motor.

The hexagonal pump shaft guarantees an effective impeller driving.

A stainless steel non-return valve is fitted in the discharge to prevent any back flow of water and alleviate any water hammer to the pump, thus safeguarding impellers and diffusers.

The GS series pumps can be coupled to either the 4OS or L4C motors.

MOTOR

For the motor characteristics, please see the relevant motor section.

Different voltages and frequencies.

| Components | Material | ||

| Europa | USA | ||

| Delivery port | Stainless steel | EN 10213-4-GX5CrNi19-10 (1.4308) | CF-8 ASTM A743 |

| Valve cap | Stainless steel | EN 10088-1-X5CrNi18-10 (1.4301) | AISI 304 |

| Valve support | Stainless steel | EN 10088-1-X5CrNi18-10 (1.4301) | AISI 304 |

| Valve gasket | Nitril rubber (NBR) | ||

| Valve locking ring | Stainless steel | DIN 17006 - X5CrNi18-7 (1.4319) | AISI 302 |

| Upper support, Diffuser, Impeller | Lexan® | ||

| Bush bearing | Laripur® | ||

| Split ring | Stainless steel | EN 10088-1-X5CrNiMo17-12-2 (1.4401) | AISI 316 |

| Stage housing, shim, Pump shaft, Outer sleeve, Spacer, Filter |

Stainless steel | EN 10088-1-X5CrNi18-10 (1.4301) | AISI 304 |

| Adapter | Stainless steel | EN 10213-4-GX5CrNi19-10 (1.4308) | CF-8 ASTM A743 |

| Coupling | Stainless steel | EN 10088-1-X5CrNi18-10 (1.4301) | AISI 304 |

| Cable cover screw | Stainless steel | EN 10088-1-X5CrNiMo17-12-2 (1.4401) | AISI 316 |

| Cable cover | Stainless steel | EN 10088-1-X5CrNi18-10 (1.4301) | AISI 304 |

| Pump type | N. of stages | Motor power | Delivery | ||||||

| l/min 0 | 8,3 | 10 | 15 | 20 | 25 | ||||

| m³/h 0 | 0,5 | 0,6 | 0,9 | 1,2 | 1,35 | ||||

| kW | HP | H= total head metres column of water | |||||||

| 1GSL02(1) | 8 | 0,37 | 0,5 | 53 | 46,6 | 45 | 37 | 27 | 20,6 |

| 1GSL03 | 12 | 0,37 | 0,5 | 79,4 | 69,9 | 67 | 55 | 40 | 30,9 |

| 1GSL05 | 18 | 0,55 | 0,75 | 119 | 105 | 100 | 83 | 60 | 46,3 |

| 1GSL07 | 24 | 0,75 | 1 | 159 | 140 | 133 | 110 | 80 | 61,7 |

| 1GSL11 | 35 | 1,1 | 1,5 | 232 | 204 | 194 | 160 | 116 | 90 |

| 1GSL15 | 49 | 1,5 | 2 | 324 | 285 | 272 | 224 | 163 | 126 |

(1) Max. pump absorbed power: 0,25 kW - 0,33 HP.

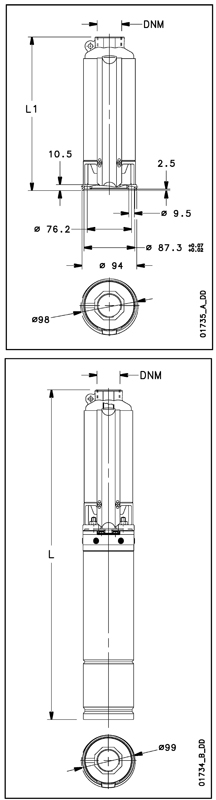

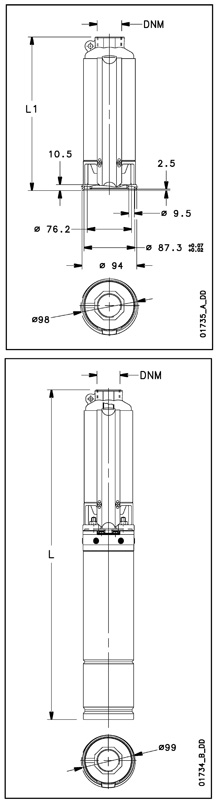

| electro pump | N. of stages | DNM | Dimensions | weight | ||

| pump | electro pump | |||||

| L1 | L | kg | kg | |||

| single-phase motor | Rp 1¼" | |||||

| 1GSL02M-4OS | 8 | 298 | 651 | 3,1 | 10,7 | |

| 1GSL03M-4OS | 12 | 369 | 722 | 3,9 | 11,5 | |

| 1GSL05M-4OS | 18 | 472 | 825 | 4,9 | 13,1 | |

| 1GSL07M-4OS | 24 | 578 | 956 | 5,8 | 15,1 | |

| 1GSL11M-4OS | 35 | 824 | 1237 | 8,7 | 19,9 | |

| 1GSL15M-4OS | 49 | 1068 | 1516 | 11,8 | 24,6 | |

| three-phase motor | ||||||

| 1GSL03T-4OS | 12 | 369 | 701 | 3,9 | 11 | |

| 1GSL05T-4OS | 18 | 472 | 825 | 4,9 | 12,5 | |

| 1GSL07T-4OS | 24 | 578 | 931 | 5,8 | 14 | |

| 1GSL11T-4OS | 35 | 824 | 1202 | 8,7 | 18 | |

| 1GSL15T-4OS | 49 | 1068 | 1481 | 11,8 | 23,2 | |

| electro pump | N. of stages | DNM | Dimensions | weight | ||

| pump | electro pump | |||||

| L1 | L | kg | kg | |||

| single-phase motor | Rp 1¼" | |||||

| 1GSL02M-L4C | 8 | 298 | 532 | 3,1 | 10,3 | |

| 1GSL03M-L4C | 12 | 369 | 603 | 3,9 | 11,2 | |

| 1GSL05M-L4C | 18 | 472 | 736 | 4,9 | 12,7 | |

| 1GSL07M-L4C | 24 | 578 | 862 | 5,8 | 14,2 | |

| 1GSL11M-L4C | 35 | 824 | 1153 | 8,7 | 19,6 | |

| 1GSL15M-L4C | 49 | 1068 | 1459 | 11,8 | 24,5 | |

| three-phase motor | ||||||

| 1GSL03T-L4C | 12 | 369 | 583 | 3,9 | 10,9 | |

| 1GSL05T-L4C | 18 | 472 | 706 | 4,9 | 12,1 | |

| 1GSL07T-L4C | 24 | 578 | 842 | 5,8 | 13,6 | |

| 1GSL11T-L4C | 35 | 824 | 1108 | 8,7 | 17,1 | |

| 1GSL15T-L4C | 49 | 1068 | 1414 | 11,8 | 23,8 | |

*Electric pumps exceeding 1500 mm in lenght are supplied uncoupled. Motor and Pump are packed separatly.

Deep well pump

| Pump type | N. of stages | Motor power | Delivery | ||||||

| l/min 0 | 20 | 25 | 30 | 40 | 50 | ||||

| m³/h 0 | 1,2 | 1,5 | 1,8 | 2,4 | 3 | ||||

| kW | HP | H= total head metres column of water | |||||||

| 2GS02(1) | 5 | 0,37 | 0,5 | 33 | 30 | 28 | 26 | 20 | 13 |

| 2GS03 | 7 | 0,37 | 0,5 | 47 | 42 | 40 | 36 | 29 | 19 |

| 2GS05 | 10 | 0,55 | 0,75 | 67 | 60 | 56 | 52 | 41 | 27 |

| 2GS07 | 14 | 0,75 | 1 | 93 | 83 | 79 | 73 | 57 | 37 |

| 2GS11 | 20 | 1,1 | 1,5 | 133 | 119 | 113 | 104 | 82 | 53 |

| 2GS15 | 28 | 1,5 | 2 | 187 | 167 | 158 | 146 | 115 | 74 |

| 2GS22 | 40 | 2,2 | 3 | 267 | 238 | 226 | 208 | 164 | 106 |

| 2GS30 | 52 | 3 | 4 | 347 | 309 | 294 | 271 | 213 | 138 |

(1) Max. pump absorbed power: 0,25 kW - 0,33 HP.

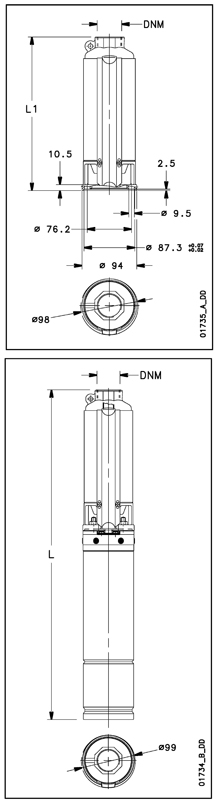

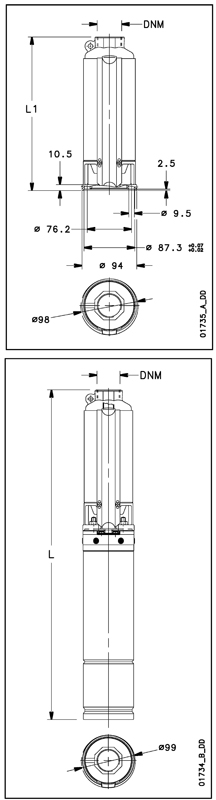

| electro pump | N. of stages | DNM | Dimensions | weight | ||

| pump | electro pump | |||||

| L1 | L | kg | kg | |||

| single-phase motor | Rp 1¼" | |||||

| 2GS02M-4OS | 5 | 245 | 598 | 2,6 | 10,2 | |

| 2GS03M-4OS | 7 | 280 | 633 | 2,9 | 10,5 | |

| 2GS05M-4OS | 10 | 332 | 685 | 3,5 | 11,7 | |

| 2GS07M-4OS | 14 | 402 | 780 | 4,2 | 13,5 | |

| 2GS11M-4OS | 20 | 507 | 920 | 5,3 | 16,5 | |

| 2GS15M-4OS | 28 | 680 | 1128 | 7,1 | 19,9 | |

| 2GS22M-4OS | 40 | 914 | 1412 | 10,1 | 25,2 | |

| three-phase motor | ||||||

| 2GS03T-4OS | 7 | 280 | 612 | 2,9 | 10 | |

| 2GS05T-4OS | 10 | 332 | 685 | 3,5 | 11,1 | |

| 2GS07T-4OS | 14 | 402 | 755 | 4,2 | 12,4 | |

| 2GS11T-4OS | 20 | 507 | 885 | 5,3 | 14,6 | |

| 2GS15T-4OS | 28 | 680 | 1093 | 7,1 | 18,5 | |

| 2GS22T-4OS | 40 | 914 | 1362 | 10,1 | 23 | |

| 2GS30T-4OS | 52 | 1120 | 1568 | 12,2 | 26,1 | |

| electro pump | N. of stages | DNM | Dimensions | weight | ||

| pump | electro pump | |||||

| L1 | L | kg | kg | |||

| single-phase motor | Rp 1¼" | |||||

| 2GS02M-L4C | 5 | 245 | 479 | 2,6 | 9,8 | |

| 2GS03M-L4C | 7 | 280 | 514 | 2,9 | 10,1 | |

| 2GS05M-L4C | 10 | 332 | 596 | 3,5 | 11,3 | |

| 2GS07M-L4C | 14 | 402 | 686 | 4,2 | 12,6 | |

| 2GS11M-L4C | 20 | 507 | 836 | 5,3 | 16,2 | |

| 2GS15M-L4C | 28 | 680 | 1071 | 7,1 | 19,8 | |

| 2GS22M-L4C | 40 | 914 | 1325 | 10,1 | 24,3 | |

| three-phase motor | ||||||

| 2GS03T-L4C | 7 | 280 | 494 | 2,9 | 9,9 | |

| 2GS05T-L4C | 10 | 332 | 566 | 3,5 | 10,7 | |

| 2GS07T-L4C | 14 | 402 | 666 | 4,2 | 12 | |

| 2GS11T-L4C | 20 | 507 | 791 | 5,3 | 13,7 | |

| 2GS15T-L4C | 28 | 680 | 1026 | 7,1 | 19,1 | |

| 2GS22T-L4C | 40 | 914 | 1305 | 10,1 | 22,9 | |

| 2GS30T-L4C | 52 | 1120 | 1662 | 12,2 | 32,8 | |

*Electric pumps exceeding 1500 mm in lenght are supplied uncoupled. Motor and Pump are packed separatly.

Deep well pump

| Pump type | N. of stages | Motor power | Delivery | ||||||

| l/min 0 | 30 | 40 | 60 | 80 | 90 | ||||

| m³/h 0 | 1,8 | 2,4 | 3,6 | 4,8 | 5,4 | ||||

| kW | HP | H= total head metres column of water | |||||||

| 4GS03M | 4 | 0,37 | 0,5 | 27 | 24 | 23 | 19 | 13 | 9 |

| 4GS05M | 7 | 0,55 | 0,75 | 47 | 42 | 40 | 33 | 22 | 15 |

| 4GS07M | 9 | 0,75 | 1 | 60 | 54 | 51 | 42 | 28 | 19 |

| 4GS11M | 14 | 1,1 | 1,5 | 94 | 84 | 80 | 66 | 44 | 30 |

| 4GS15M | 19 | 1,5 | 2 | 127 | 114 | 108 | 89 | 60 | 40 |

| 4GS22M | 27 | 2,2 | 3 | 181 | 162 | 154 | 127 | 85 | 57 |

| 4GS30T | 35 | 3 | 4 | 228 | 204 | 194 | 160 | 107 | 72 |

| 4GS40T | 48 | 4 | 5,5 | 321 | 288 | 274 | 226 | 151 | 102 |

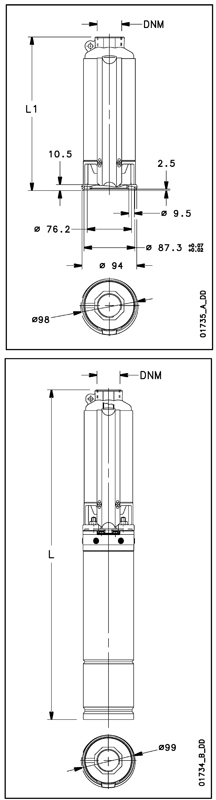

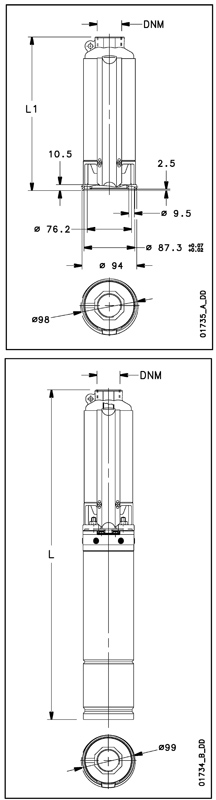

| electro pump | N. of stages | DNM | Dimensions | weight | ||

| pump | electro pump | |||||

| L1 | L | kg | kg | |||

| single-phase motor | Rp 1¼" | |||||

| 4GS03M-4OS | 4 | 245 | 598 | 2,5 | 10,1 | |

| 4GS05M-4OS | 7 | 309 | 662 | 3,1 | 11,3 | |

| 4GS07M-4OS | 9 | 352 | 730 | 3,5 | 12,8 | |

| 4GS11M-4OS | 14 | 460 | 873 | 4,6 | 15,8 | |

| 4GS15M-4OS | 19 | 568 | 1016 | 5,7 | 18,5 | |

| 4GS22M-4OS | 27 | 770 | 1268 | 7,6 | 22,7 | |

| three-phase motor | ||||||

| 4GS03T-4OS | 4 | 245 | 577 | 2,5 | 9,6 | |

| 4GS05T-4OS | 7 | 309 | 662 | 3,1 | 10,7 | |

| 4GS07T-4OS | 9 | 352 | 705 | 3,5 | 11,7 | |

| 4GS11T-4OS | 14 | 460 | 838 | 4,6 | 13,9 | |

| 4GS15T-4OS | 19 | 568 | 981 | 5,7 | 17,1 | |

| 4GS22T-4OS | 27 | 770 | 1218 | 7,6 | 20,5 | |

| 4GS30T-4OS | 35 | 967 | 1415 | 9,6 | 23,5 | |

| 4GS40T-4OS | 48 | 1248 | 1816 | 12,8 | 30,6 | |

| electro pump | N. of stages | DNM | Dimensions | weight | ||

| pump | electro pump | |||||

| L1 | L | kg | kg | |||

| single-phase motor | Rp 1¼" | |||||

| 4GS03M-L4C | 4 | 245 | 479 | 2,5 | 9,7 | |

| 4GS05M-L4C | 7 | 309 | 573 | 3,1 | 10,9 | |

| 4GS07M-L4C | 9 | 352 | 636 | 3,5 | 11,9 | |

| 4GS11M-L4C | 14 | 460 | 789 | 4,6 | 15,5 | |

| 4GS15M-L4C | 19 | 568 | 959 | 5,7 | 18,4 | |

| 4GS22M-L4C | 27 | 770 | 1181 | 7,6 | 21,8 | |

| three-phase motor | ||||||

| 4GS03T-L4C | 4 | 245 | 459 | 2,5 | 9,5 | |

| 4GS05T-L4C | 7 | 309 | 543 | 3,1 | 10,3 | |

| 4GS07T-L4C | 9 | 352 | 616 | 3,5 | 11,3 | |

| 4GS11T-L4C | 14 | 460 | 744 | 4,6 | 13 | |

| 4GS15T-L4C | 19 | 568 | 914 | 5,7 | 17,7 | |

| 4GS22T-L4C | 27 | 770 | 1161 | 7,6 | 20,4 | |

| 4GS30T-L4C | 35 | 967 | 1509 | 9,6 | 30,2 | |

| 4GS40T-L4C | 48 | 1248 | 1860 | 12,8 | 36,5 | |

*Electric pumps exceeding 1500 mm in lenght are supplied uncoupled. Motor and Pump are packed separatly.

Deep well pump

| Pump type | N. of stages | Motor power | Delivery | ||||||

| l/min 0 | 50 | 70 | 90 | 110 | 133 | ||||

| m³/h 0 | 3 | 4,2 | 5,4 | 6,6 | 8 | ||||

| kW | HP | H= total head metres column of water | |||||||

| 6GS05 | 5 | 0,55 | 0,75 | 30,5 | 25,8 | 23 | 21 | 17 | 11,5 |

| 6GS07 | 7 | 0,75 | 1 | 42,7 | 36,1 | 33 | 29 | 24 | 16,1 |

| 6GS11 | 10 | 1,1 | 1,5 | 61 | 51,6 | 47 | 41 | 34 | 23 |

| 6GS15 | 14 | 1,5 | 2 | 85,4 | 72,2 | 66 | 58 | 48 | 32,2 |

| 6GS22 | 21 | 2,2 | 3 | 128 | 108 | 99 | 87 | 71 | 48,3 |

| 6GS30 | 29 | 3 | 4 | 177 | 150 | 136 | 120 | 99 | 66,7 |

| 6GS40 | 38 | 4 | 5,5 | 232 | 196 | 179 | 157 | 129 | 87,4 |

| 6GS55 | 52 | 5,5 | 7,5 | 317 | 268 | 244 | 215 | 177 | 120 |

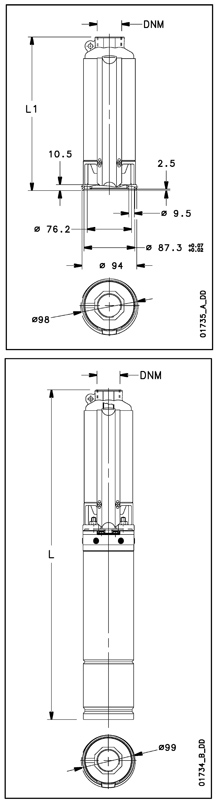

| electro pump | N. of stages | DNM | Dimensions | weight | ||

| pump | electro pump | |||||

| L1 | L | kg | kg | |||

| single-phase motor | Rp 1¼" | |||||

| 6GS05M-4OS | 5 | 329 | 682 | 3,5 | 11,7 | |

| 6GS07M-4OS | 7 | 390 | 768 | 4,2 | 13,5 | |

| 6GS11M-4OS | 10 | 485 | 898 | 5,1 | 16,3 | |

| 6GS15M-4OS | 14 | 645 | 1093 | 6,8 | 19,6 | |

| 6GS22M-4OS | 21 | 862 | 1360 | 9,1 | 24,2 | |

| three-phase motor | ||||||

| 6GS05T-4OS | 5 | 329 | 682 | 3,5 | 11,1 | |

| 6GS07T-4OS | 7 | 390 | 743 | 4,2 | 12,4 | |

| 6GS11T-4OS | 10 | 485 | 863 | 5,1 | 14,4 | |

| 6GS15T-4OS | 14 | 645 | 1058 | 6,8 | 18,2 | |

| 6GS22T-4OS | 21 | 862 | 1310 | 9,1 | 22 | |

| 6GS30T-4OS | 29 | 1127 | 1575 | 11,8 | 25,7 | |

| 6GS40T-4OS | 38 | 1406 | 1974 | 14,7 | 32,5 | |

| 6GS55T-4OS | 52 | 1840 | 2468 | 19,3 | 40,6 | |

| electro pump | N. of stages | DNM | Dimensions | weight | ||

| pump | electro pump | |||||

| L1 | L | kg | kg | |||

| single-phase motor | Rp 1¼" | |||||

| 6GS05M-L4C | 5 | 329 | 593 | 3,5 | 11,3 | |

| 6GS07M-L4C | 7 | 390 | 674 | 4,2 | 12,6 | |

| 6GS11M-L4C | 10 | 485 | 814 | 5,1 | 16 | |

| 6GS15M-L4C | 14 | 645 | 1036 | 6,8 | 19,5 | |

| 6GS22M-L4C | 21 | 862 | 1273 | 9,1 | 23,3 | |

| three-phase motor | ||||||

| 6GS05T-L4C | 5 | 329 | 563 | 3,5 | 10,7 | |

| 6GS07T-L4C | 7 | 390 | 654 | 4,2 | 12 | |

| 6GS11T-L4C | 10 | 485 | 769 | 5,1 | 13,5 | |

| 6GS15T-L4C | 14 | 645 | 991 | 6,8 | 18,8 | |

| 6GS22T-L4C | 21 | 862 | 1253 | 9,1 | 21,9 | |

| 6GS30T-L4C | 29 | 1127 | 1669 | 11,8 | 32,4 | |

| 6GS40T-L4C | 38 | 1406 | 2018 | 14,7 | 38,4 | |

| 6GS55T-L4C | 52 | 1840 | 2522 | 19,3 | 46,3 | |

*Electric pumps exceeding 1500 mm in lenght are supplied uncoupled. Motor and Pump are packed separatly.

Deep well pump

| Pump type | N. of stages | Motor power | Delivery | ||||||

| l/min 0 | 67 | 100 | 120 | 140 | 183 | ||||

| m³/h 0 | 4 | 6 | 7,2 | 8,4 | 11 | ||||

| kW | HP | H= total head metres column of water | |||||||

| 8GS07 | 4 | 0,75 | 1 | 26 | 23 | 22 | 20 | 18 | 11 |

| 8GS11 | 6 | 1,1 | 1,5 | 39 | 35 | 33 | 31 | 28 | 17 |

| 8GS15 | 8 | 1,5 | 2 | 52 | 46 | 44 | 41 | 37 | 22 |

| 8GS22 | 13 | 2,2 | 3 | 85 | 75 | 71 | 67 | 60 | 36 |

| 8GS30 | 17 | 3 | 4 | 111 | 98 | 93 | 87 | 78 | 47 |

| 8GS40 | 23 | 4 | 5,5 | 150 | 133 | 126 | 118 | 106 | 63 |

| 8GS55 | 32 | 5,5 | 7,5 | 208 | 185 | 175 | 164 | 147 | 88 |

| 8GS75 | 43 | 7,5 | 10 | 280 | 249 | 235 | 220 | 198 | 118 |

| electro pump | N. of stages | DNM | Dimensions | weight | ||

| pump | electro pump | |||||

| L1 | L | kg | kg | |||

| single-phase motor | Rp 2" | |||||

| 8GS07M-4OS | 4 | 299 | 677 | 3,2 | 12,5 | |

| 8GS11M-4OS | 6 | 361 | 774 | 3,8 | 15 | |

| 8GS15M-4OS | 8 | 423 | 871 | 4,5 | 17,3 | |

| 8GS22M-4OS | 13 | 580 | 1078 | 6 | 21,1 | |

| three-phase motor | ||||||

| 8GS07T-4OS | 4 | 299 | 652 | 3,2 | 11,4 | |

| 8GS11T-4OS | 6 | 361 | 739 | 3,8 | 13,1 | |

| 8GS15T-4OS | 8 | 423 | 836 | 4,5 | 15,9 | |

| 8GS22T-4OS | 13 | 580 | 1028 | 6 | 18,9 | |

| 8GS30T-4OS | 17 | 740 | 1188 | 7,8 | 21,7 | |

| 8GS40T-4OS | 23 | 926 | 1494 | 9,6 | 27,4 | |

| 8GS55T-4OS | 32 | 1224 | 1852 | 12,8 | 34,1 | |

| 8GS75T-4OS | 43 | 1563 | 2397 | 16,2 | 45 | |

| electro pump | N. of stages | DNM | Dimensions | weight | ||

| pump | electro pump | |||||

| L1 | L | kg | kg | |||

| single-phase motor | Rp 2" | |||||

| 8GS07M-L4C | 4 | 299 | 583 | 3,2 | 11,6 | |

| 8GS11M-L4C | 6 | 361 | 690 | 3,8 | 14,7 | |

| 8GS15M-L4C | 8 | 423 | 814 | 4,5 | 17,2 | |

| 8GS22M-L4C | 13 | 580 | 991 | 6 | 20,2 | |

| three-phase motor | ||||||

| 8GS07T-L4C | 4 | 299 | 563 | 3,2 | 11 | |

| 8GS11T-L4C | 6 | 361 | 645 | 3,8 | 12,2 | |

| 8GS15T-L4C | 8 | 423 | 769 | 4,5 | 16,5 | |

| 8GS22T-L4C | 13 | 580 | 971 | 6 | 18,8 | |

| 8GS30T-L4C | 17 | 740 | 1282 | 7,8 | 28,4 | |

| 8GS40T-L4C | 23 | 926 | 1538 | 9,6 | 33,3 | |

| 8GS55T-L4C | 32 | 1224 | 1906 | 12,8 | 39,8 | |

| 8GS75T-L4C | 43 | 1563 | 2325 | 16,2 | 45,4 | |

*Electric pumps exceeding 1500 mm in lenght are supplied uncoupled. Motor and Pump are packed separatly.

Deep well pump

| Pump type | N. of stages | Motor power | Delivery | ||||||

| l/min 0 | 100 | 150 | 175 | 200 | 250 | ||||

| m³/h 0 | 6 | 9 | 10,5 | 12 | 15 | ||||

| kW | HP | H= total head metres column of water | |||||||

| 12GS15 | 7 | 1,5 | 2 | 43,9 | 37,3 | 31 | 28 | 24 | 14,6 |

| 12GS22 | 11 | 2,2 | 3 | 69 | 58,4 | 49 | 43 | 37 | 22,5 |

| 12GS30 | 15 | 3 | 4 | 94 | 79,4 | 67 | 59 | 50 | 30 |

| 12GS40 | 20 | 4 | 5,5 | 128,6 | 109,9 | 94 | 84 | 73 | 46 |

| 12GS55 | 27 | 5,5 | 7,5 | 173,6 | 148,3 | 127 | 113 | 98 | 62 |

| 12GS75 | 35 | 7,5 | 10 | 221,8 | 190,2 | 163 | 146 | 126 | 80 |

| electro pump | N. of stages | DNM | Dimensions | weight | ||

| pump | electro pump | |||||

| L1 | L | kg | kg | |||

| single-phase motor | Rp 2" | |||||

| 12GS15M-4OS | 7 | 539 | 987 | 5,2 | 18 | |

| 12GS22M-4OS | 11 | 785 | 1283 | 7,9 | 23 | |

| three-phase motor | ||||||

| 12GS15T-4OS | 7 | 539 | 952 | 5,2 | 16,6 | |

| 12GS22T-4OS | 11 | 785 | 1233 | 7,9 | 20,8 | |

| 12GS30T-4OS | 15 | 992 | 1440 | 10 | 23,9 | |

| 12GS40T-4OS | 20 | 1252 | 1820 | 12,6 | 30,4 | |

| 12GS55T-4OS | 27 | 1634 | 2262 | 16,8 | 38,1 | |

| 12GS75T-4OS | 35 | 2049 | 2883 | 20,9 | 49,7 | |

| electro pump | N. of stages | DNM | Dimensions | weight | ||

| pump | electro pump | |||||

| L1 | L | kg | kg | |||

| single-phase motor | Rp 2" | |||||

| 12GS15M-L4C | 7 | 539 | 930 | 5,2 | 17,9 | |

| 12GS22M-L4C | 11 | 785 | 1196 | 7,9 | 22,1 | |

| three-phase motor | ||||||

| 12GS15T-L4C | 7 | 539 | 885 | 5,2 | 17,2 | |

| 12GS22T-L4C | 11 | 785 | 1176 | 7,9 | 20,7 | |

| 12GS30T-L4C | 15 | 992 | 1534 | 10 | 30,6 | |

| 12GS40T-L4C | 20 | 1252 | 1864 | 12,6 | 36,3 | |

| 12GS55T-L4C | 27 | 1634 | 2316 | 16,8 | 43,8 | |

| 12GS75T-L4C | 35 | 2049 | 2811 | 20,9 | 50,1 | |

*Electric pumps exceeding 1500 mm in lenght are supplied uncoupled. Motor and Pump are packed separatly.

Deep well pump

| Pump type | N. of stages | Motor power | Delivery | ||||||

| l/min 0 | 133 | 200 | 250 | 300 | 367 | ||||

| m³/h 0 | 8 | 12 | 15 | 18 | 22 | ||||

| kW | HP | H= total head metres column of water | |||||||

| 16GS22 | 9 | 2,2 | 3 | 49,5 | 40,3 | 34 | 29 | 23 | 14 |

| 16GS30 | 12 | 3 | 4 | 66 | 54 | 46 | 39 | 31 | 20,4 |

| 16GS40 | 16 | 4 | 5,5 | 92,1 | 74,9 | 64 | 54 | 44 | 29 |

| 16GS55 | 21 | 5,5 | 7,5 | 120,9 | 98,6 | 84 | 72 | 59 | 39 |

| 16GS75 | 28 | 7,5 | 10 | 161,2 | 131,5 | 112 | 96 | 78 | 52 |

| electro pump | N. of stages | DNM | Dimensions | weight | ||

| pump | electro pump | |||||

| L1 | L | kg | kg | |||

| single-phase motor | Rp 2" | |||||

| 16GS22M-4OS | 9 | 749 | 1247 | 7,7 | 22,8 | |

| three-phase motor | ||||||

| 16GS22T-4OS | 9 | 749 | 1197 | 7,7 | 20,6 | |

| 16GS30T-4OS | 12 | 953 | 1401 | 9,7 | 23,6 | |

| 16GS40T-4OS | 16 | 1224 | 1792 | 12,4 | 30,2 | |

| 16GS55T-4OS | 21 | 1620 | 2248 | 16,5 | 37,8 | |

| 16GS75T-4OS | 28 | 2096 | 2930 | 21,2 | 50 | |

| electro pump | N. of stages | DNM | Dimensions | weight | ||

| pump | electro pump | |||||

| L1 | L | kg | kg | |||

| single-phase motor | Rp 2" | |||||

| 16GS22M-L4C | 9 | 749 | 1160 | 7,7 | 21,9 | |

| three-phase motor | ||||||

| 16GS22T-L4C | 9 | 749 | 1140 | 7,7 | 20,5 | |

| 16GS30T-L4C | 12 | 953 | 1495 | 9,7 | 30,3 | |

| 16GS40T-L4C | 16 | 1224 | 1836 | 12,4 | 36,1 | |

| 16GS55T-L4C | 21 | 1620 | 2302 | 16,5 | 43,5 | |

| 16GS75T-L4C | 28 | 2096 | 2858 | 21,2 | 50,4 | |

*Electric pumps exceeding 1500 mm in lenght are supplied uncoupled. Motor and Pump are packed separatly.